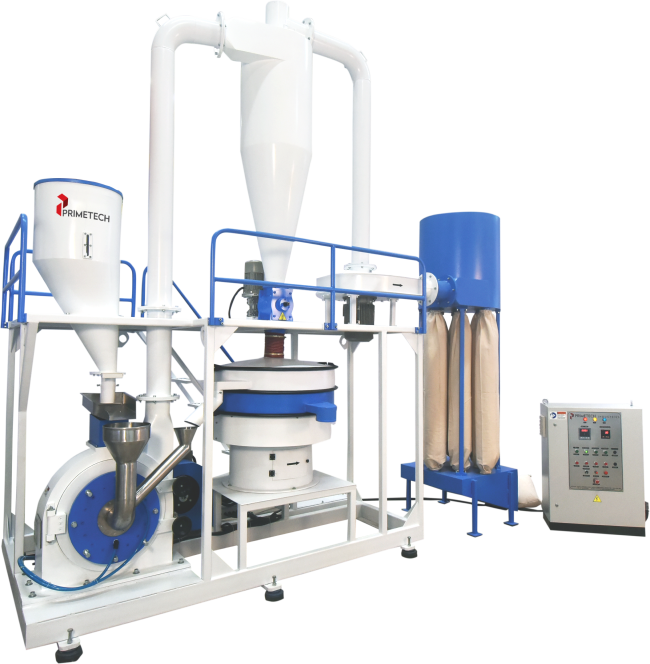

Pulverizer

'Your Reliable Partner for PLASTIC SIZE REDUCTION'

Applications

- Lldpe powder for rotomoulding

- Recycling of extrusion scrap waste

- PVC pipes and profiles

- CPVC pipes

- WPC boards and profiles

- PU

- UHMW

- Masterbatching application and various thermoplastic material

High Speed Precision Pulverizers

The Primetech PP-series of disc pulverizers are high speed, precision grinders suitable for processing of medium hard, impact resistant and brittle materials.

Typical applications are; pulverizing of granules to powder for rotomoulding, masterbatch compounding, wood, PVC, WPC industry, etc.

The material to be pulverized is introduced through the center of a vertical fixed grinding disc which is mounted concentrically with an identical high speed rotating disc. Centrifugal force carries the material through the grinding area and the resultant powder is collected with a blower and cyclone system. The Primetech PP series pulverizers have several technical advantages which ensure ideal performance and operation.

Product Key Attributes

- Low power consumption with high throughput

- Economical production cost with consistent output and quality

- Low maintenance

- Minimum man power requirement

- Grinding discs made from German high grade alloy steel

- Cooling provision for stationery disc, mill body, duct line, bearings and housing

- Monitoring of main motor load and control system

- Monitoring of powder temperature and control system (optional)

- Microprocessor based machine control panel with digital display (optional)

- Exact and easy grinding gap adjustment

- Housing design for optimized water-cooling

- Easy to clean

- Broad application field

- Economical and cost effective

- Robust in design

- Quality of powder according to specifications

We Offer

- One-piece grinding disc made from German high grade alloy steel

- Superior grinding disc surface treatment to boost up its wear life

- Advance bearing technology

- Easy adjustments of disc gap

- Unique design of housing

- High efficiency blower and vibro-screen

- Powerful dual cooling with water and air

Your Advantage

- Pulverizing without using liquid nitrogen

- Excellent flow rate and mixing possibility of the powder

- Compact construction, minimum space requirement

- Most economical and cost effective

- Narrow particle size distribution with low fines content

- Automatic load and temperature controller

- Fully automatic continuous operation

- Safety interlock system

- Low power consumption with high throughput

- Economical production cost with consistent output and quality

- Low maintenance

- Minimum man power requirement

- Grinding discs are made from German high grade alloy steel

- Cooling provision for stationery disk, mill body, duct line, bearing and housing

- Monitoring of main motor load and control system

- Monitoring of powder temperature and control system (optional)

- Microprocessor based machine control panel with digital display (optional)

- Exact and easy grinding gap adjustment

- Housing design for optimized water-cooling

- Easy to clean

- Broad application field

- Economical and cost effective

- Robust in design

- Quality of powder according to specifications

Output Range

| Model | Motor Capacity (kw) | Output Capacity |

|---|---|---|

| PP300 | 15 | 120-200 |

| PP400 | 30 | 200-300 |

| PP600 | 55 | 400-600 |

Output Range / Masterbatch

| Model | Motor Capacity (kw) | Output Capacity |

|---|---|---|

| PP100 | 15 | 100-125 |

| PP200 | 22 | 150-200 |

| PP300 | 37 | 350-400 |

Our Growth Partners

Get in Touch

Address

Plot No. 4716 & 4717, Phase 4,

Opp. Water Tank, GIDC Vatva,

Ahmedabad - 382 445

Gujarat. India